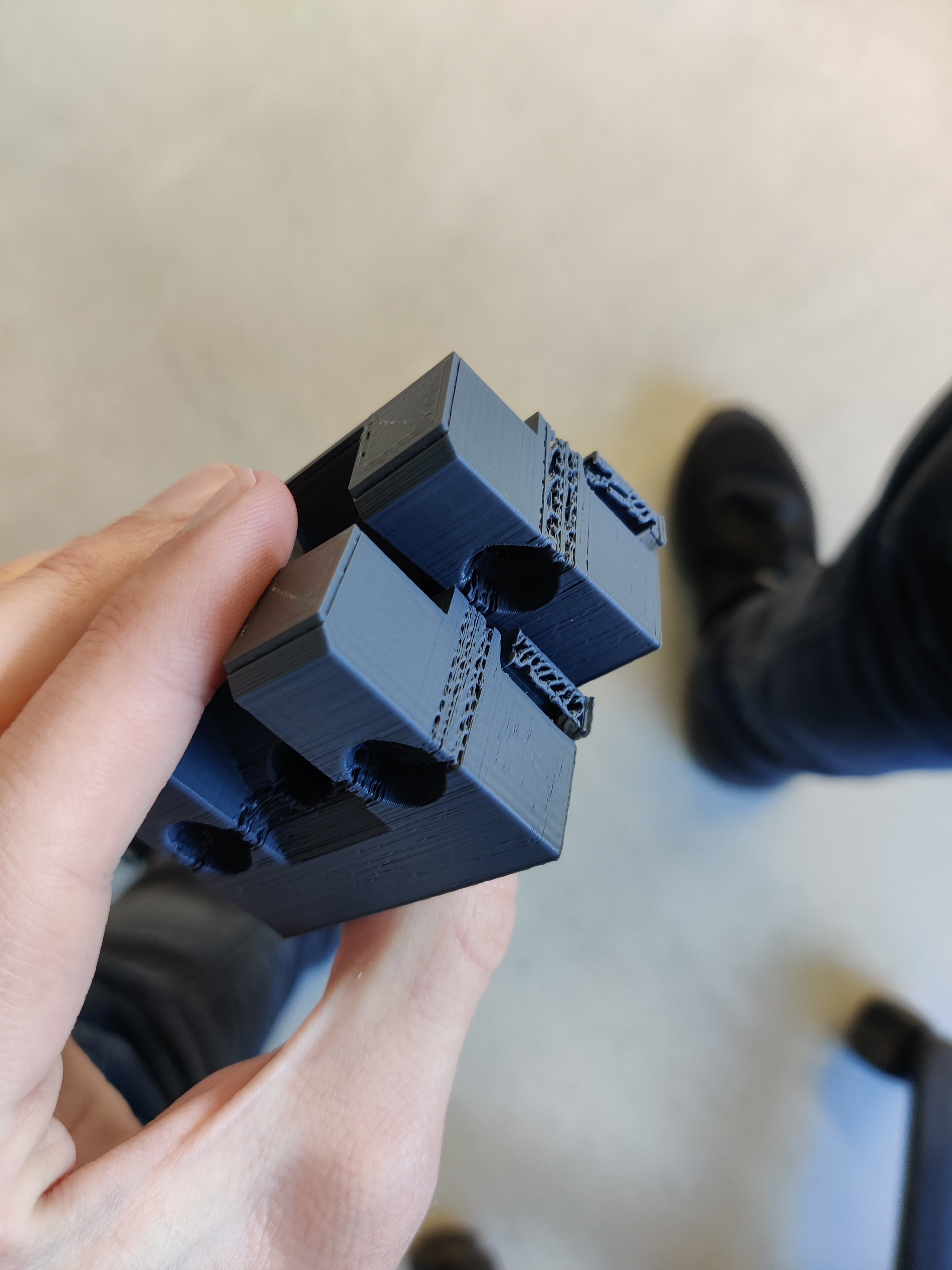

Im working with an old reprap cotroled directly with an Laptop with cura. Filament is RS-Pro (2325395) Pla though. Open around 4 weeks ago but i have this problem in some capacity since i have this Filament. Before i had some really old pla which snapped all the time because it wss so brittle. Is this really just shitty Filament? Help/ Insight would be much appreciated.

Looks like wet filament to me. Those pock marks are what happens when the moisture immediately evaporates to steam and bursts when it hits the nozzle.

old pla which snapped all the time because it wss so brittle

That’s what extremely wet PLA looks like.

depending on the situation, you can pull humidity back out of it and reuse it using a bunch of silica dessicant.

Or just toss it in the oven at a low temp for an hour or so. I’ve also turn my bed temp up high and put a spool on it with a box over it. Just cut some small holes in the too to allow humid air to come out. After an hour or so should be good to go. Assuming the issue is moist filament.

I never succeeded in drying filament with the normal cheap ways people post around.

But I’ve had plenty of luck with a filament drier. Those aren’t too expensive.

I want a filament dryer, but I’m too cheap, and don’t use my printer enough. :(

I want to start using it again, but I’ve been struggling to get the motivation to recalibrate and figure out all the optimal settings again.

I’ve had partial clogs that manifest like that.

Cold pulls (several) ended up resolving my issue.my best explanation was, that there was some debris in the nozzle, which would sometimes (nearly) seal the nozzle, and at other times be retracted with the filament, get stuck somewhere else and filament flows freely.

Yeah, I don’t use much PLA but this looks like a partial clog, you can see that where you have long stretches of extrusion it works fine, but when it starts retracting it clogs.

It could very well be that it’s clogging BECAUSE it’s shitty or wet filament, tho. Is your nozzle screwed in correctly, heatbreak too, etc?

I’d wonder about the model or slicer. You had great printing above and below that. Unless you had a nozzle problem that cleared itself up, that’s a weird way to go bad right at that transition, and it’s very symetric on that section.

It’s your filament wet? Have you replaced the nozzle? What’s weird is the edges appear to look like oozing but you’ve done a temp towers.

have you done a temp tower with it? maybe it doesn’t like your temp settings.

I’ve used old filament plenty of times and usually it just gets stringy

i think yours is a timing or temp problem

I’ve tried multiple temp towers but they all failed because of the underextrution. So I tried benchys with with 190 and 220°C and have seen little difference. Then I just stuck to 200°C for no other reasons then I’ve used it before

Print i did immediately before. Main differences no supports and less Variationen in horizontal Crosssection ?

Definitely looks like you have some extrusion issues here. Check if the nozzle is partially clogged and that the extruder isn’t skipping.

Has the printer been used recently and put out good prints? Has anything about the setup changed including a slicer update or different slicer?

I have two knee jerk reactions

Is there an under-extruded section of the print, similar to the corner closest to the camera on the lower section of the print, on the top section of the print? You might have a retraction/priming problem. A quick retraction test print would make this pretty obvious.

You might have had a partial clog that resolved itself, but the fact that the extrusion issues change with the topology of the design makes me want to suggest something else. Try the print again. If you get the same outcome filament isn’t the primary cause.

I second partial clog

Yes the print immediately before was good (see my other commend) 2. Try same settings (left) seems a little bit better but still not good

I would strongly suspect a retraction/priming or mechanical related issue give byhe fact that it’s repeatable in the same area of the print.

I think you’re right